Product Description

TDD is our precipitated calcium carbonate coated with resin acid, with uniformed 50 nm primary particles, specifically designed for enhanced compatibility with organic materials. Surface treated calcium carbonate provides better mixing properties when added to organic materials during production. TDD is designed to be used in rubber, paint, ink and etc.

Specifications

Whiteness (%): 86 min.

Specific Gravity (g/cm3): 2.56

Bulk Density (g/mL): 0.80 max.

Surface Coating: Resin Acid

Oil Absorption (mL/100 g): 22 ~ 34

CaCO3 Content (%): 96 min.

Moisture Content (%): 1.20 max

pH Value: 8.4 ~ 9.1

Compound Guide

Natural Rubber (NR): Show the best results.

Isoprene Rubber (IR): Show the best results.

Butadiene Rubber (BR): Show excellent results.

Styrene-butadiene Rubber (SBR): Show excellent results.

Chloroprene Rubber (CR): Show excellent results.

Butyl Rubber (IIR): Show excellent results.

Hypalon (CSM): Show excellent results.

Reclaimed Rubber: Show the best results.

Polyvinyl Chloride (PVC): Show satisfactory results.

Product Usage Example

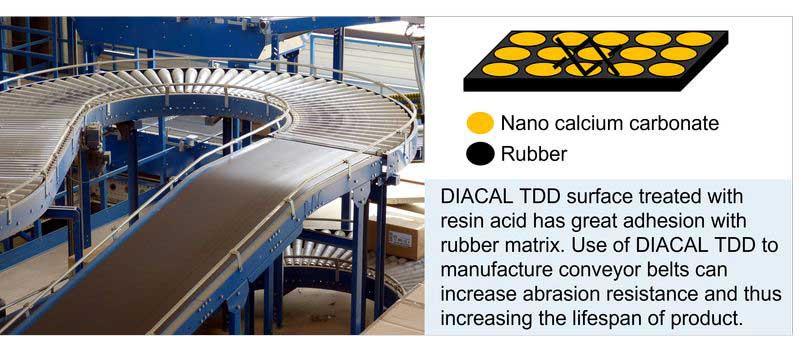

Usage of DIACAL TDD in conveyor belts

Rubber matrix is generally softer than inorganic fillers, for example calcium carbonate, addition of fillers into the rubber matrix can increase abrasion resistance, protecting the rubber matrix from friction wear. If filler particles do not bind well to the rubber matrix, it becomes loose and will fall out, exposing the rubber making it a weak point. DIACAL TDD nano calcium carbonate is surface treated is resin acid, have good wetting ability to aid with compounding and mixing of rubber with calcium carbonate particles, particles are small and can spread evenly into the matrix, increasing lifespan of conveyor belts.

Usage of DIACAL TDD used in ink

DIACAL TDD is surface treated with resin acid and is compatible with many ink formulations. Addition of DIACAL TDD nano calcium carbonate as fillers to ink can modulate consistency, viscosity and rheology properties. DIACAL TDD is highly dispersible, have low bulk density, and have good hiding power.

Product Inquiry

We provide customized OEM and ODM solutions for agriculture liquid fertilizers and nanometer calcium carbonate. Contact us today to discuss your specific needs and discover how our innovative solutions can elevate your products and business.

Language

Language

Download

Download